Mīkini ʻeli CNC PHD2020C no nā papa kila

| ʻO ka mīkini kiʻekiʻe loamea hanaka nui | Anawaena | φ2000mm |

| Pā | 2000 x 2000mm | |

| ʻO ka mānoanoa o ka papa hana i hana ʻia | 100 mm | |

| papa hana | Ka laulā o ke awāwa-T | 22 mm |

| Poʻo mana ʻeli | ʻO ke anawaena wili kiʻekiʻe loa o ka wili wili kila wikiwiki | φ50 mm |

| ʻO ke anawaena ʻeli kiʻekiʻe loa o ka wili carbide sima | φ40 mm | |

| ʻO ke anawaena ʻoki wili kiʻekiʻe loa | φ20mm | |

| ʻO ke kāʻei spindle | BT50 | |

| Mana motika nui | 22kW | |

| ʻO ka torque spindle kiʻekiʻe loa ≤750r/min | 280Nm | |

| Ka mamao mai ka ʻaoʻao haʻahaʻa o ka makawilii ka papa hana | 250—600 mm | |

| Neʻe lōʻihi Gantry (axis-x) | Ka palena kiʻekiʻe loaStʻOki | 2050 mm |

| Ka wikiwiki o ka neʻe ʻana o ke axis X | 0—8m/min | |

| Mana o ka mīkini servo X-axis | Ma kahi o 2 × 1.5kW | |

| Ka neʻe ʻana o ke poʻo mana ma ka ʻaoʻao(ʻaoʻao Y) | ʻO ka hahau ʻana o ke poʻo mana kiʻekiʻe loa | 2050mm |

| Mana o ka mīkini servo axis Y | Ma kahi o 1.5kW | |

| Ka neʻe ʻana o ke poʻo mana(ʻaoʻao Z) | Ka huakaʻi Z-axis | 350 mm |

| Mana o ka mīkini servo axis Z | Ma kahi o 1.5 kW | |

| pololei o ke kūlana | ʻO ke koʻi X,ʻO ke koʻi Y | 0.05mm |

| E hana hou i ka pololei o ke kau ʻana | ʻO ke koʻi X,ʻO ke koʻi Y | 0.025mm |

| ʻŌnaehana pneumatic | Kaomi lako ea i koi ʻia | ≥0.8MPa |

| Mana motika conveyor chip | 0. 45kW | |

| Hoʻomaʻalili | ʻAno hoʻoluʻu kūloko | hoʻoluʻu ʻana o ka ea-noe |

| ʻAno hoʻoluʻu waho | Hoʻolulu wai kaʻapuni | |

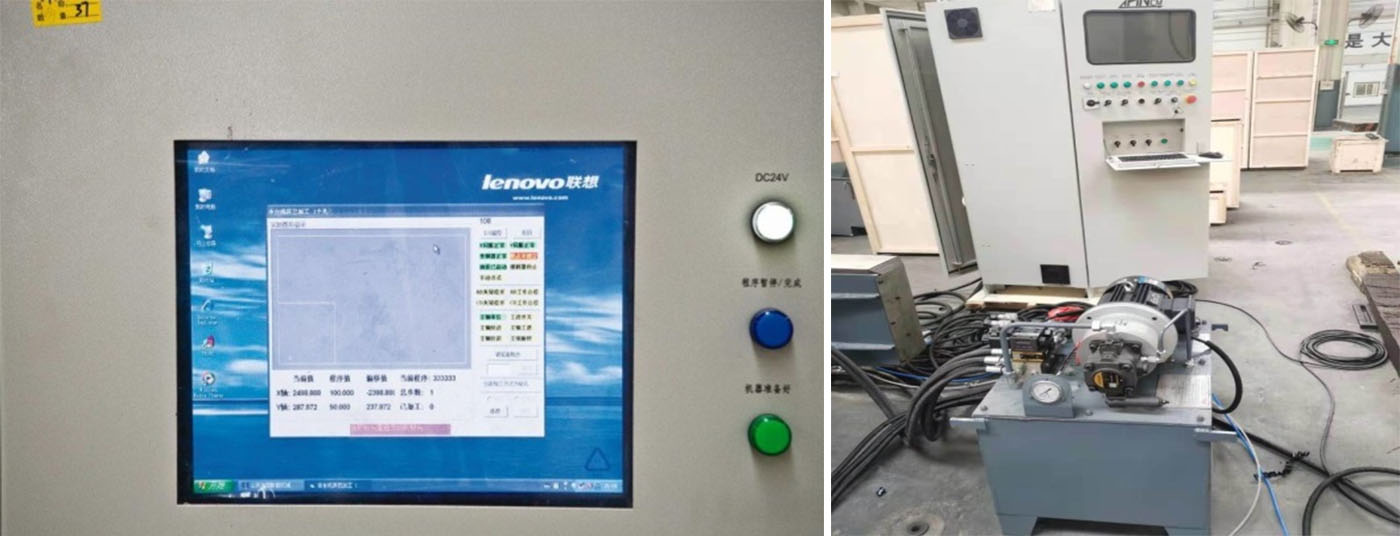

| ʻŌnaehana uila | CNC | Siemens 808D |

| Helu o nā koʻi CNC | 4 | |

| Mīkini Nui | Kaumaha | Ma kahi o 8500kg |

| Ana holoʻokoʻa(L×W×H) | Ma kahi o 5300(3300)×3130×2830 mm |

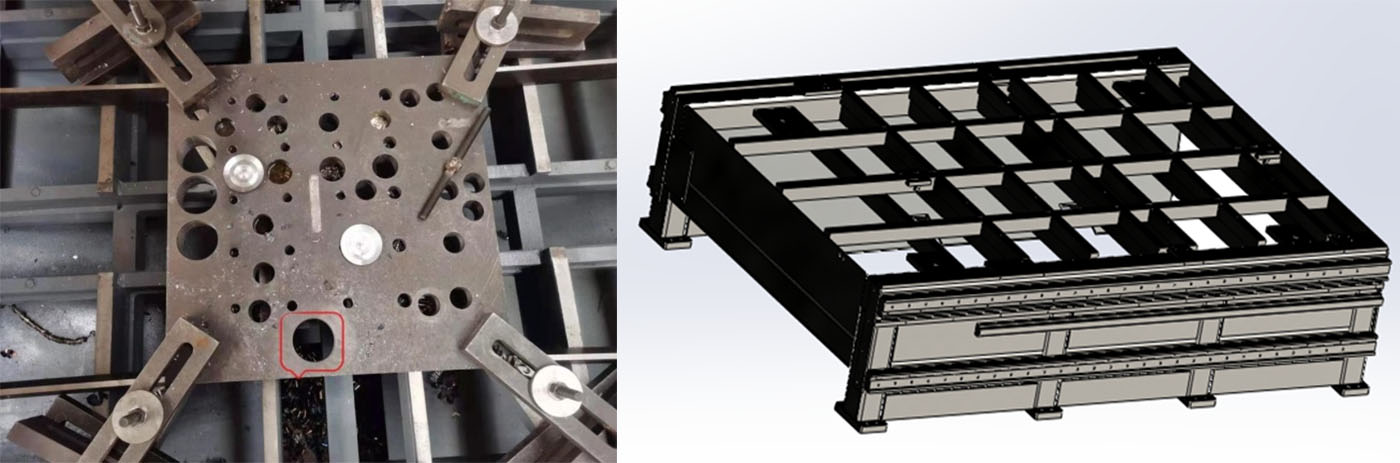

1. ʻO kēia mīkini ka mea nui i ka moena a me ka papa paheʻe longitudinal, ka gantry a me ka papa paheʻe transverse, ke poʻo mana wili, ka mea wehe ʻāpana, ka ʻōnaehana pneumatic, ka ʻōnaehana hoʻoluʻu pīpī, ka ʻōnaehana lubrication kikowaena, ka ʻōnaehana uila a me nā mea ʻē aʻe.

2. Hoʻohana ka spindle o ke poʻo mana wili i ka spindle pololei i hana ʻia ma Taiwan, me ka pololei o ka wili kiʻekiʻe a me ka paʻakikī maikaʻi. Hoʻolako ʻia me ka lua taper BT50, he mea maʻalahi ke hoʻololi i nā mea hana. Hiki iā ia ke hoʻopaʻa i ka wili wili a me ka wili carbide cemented, me kahi ākea o ka hoʻohana. Hiki ke hoʻohana ʻia nā wili hopena liʻiliʻi no ka wili māmā. Hoʻokele ʻia ka spindle e ka motika alapine loli, nona nā ʻano hoʻohana like ʻole.

3. ʻEhā mau koʻi CNC o ka mīkini: ke koʻi hoʻonoho gantry (x-axis, kaʻa pālua); ke koʻi hoʻonoho transverse (Y axis) o ke poʻo mana wili; ke koʻi hānai poʻo mana wili (Z axis). Alakaʻi ʻia kēlā me kēia koʻi CNC e ke alahao alakaʻi ʻōwili laina pololei a hoʻokele ʻia e ka motika servo AC + wili pōpō.

4. Ua lako ka mīkini me kahi mea hoʻoili ʻāpana kaulahao pālahalaha ma waenakonu o ka moena mīkini. Hoʻiliʻili ʻia nā ʻāpana hao i loko o ka mea hoʻoili ʻāpana, a lawe ʻia nā ʻāpana hao i ka mea hoʻoili ʻāpana, he mea maʻalahi loa ia no ka wehe ʻana i nā ʻāpana; Hoʻopōʻaiapuni ʻia ka mea hoʻoluʻu.

5. Ua hoʻokomo ʻia nā uhi pale palupalu ma nā ala alakaʻi axis-x a me axis-y ma nā ʻaoʻao ʻelua o ka mīkini hana.

6. Loaʻa i ka ʻōnaehana hoʻoluʻu nā hopena o ka hoʻoluʻu kūloko a me ka hoʻoluʻu waho.

7. Ua lako ka ʻōnaehana CNC o ka mīkini hana me Siemens 808D a me ka huila lima uila, nona ka hana ikaika a me ka hana maʻalahi. Ua lako me ka interface RS232 a loaʻa iā ia nā hana o ka nānā mua ʻana a me ka nānā hou ʻana. Loaʻa i ka interface hana nā hana o ke kamaʻilio kanaka-mīkini, ka uku hewa a me ka alarm aunoa, a hiki ke hoʻokō i ka papahana aunoa o CAD-CAM.

| ʻAʻOLE. | Inoa | Lama | ʻĀina |

| 1 | Lalahao alakaʻi inear | HIWIN/PMI/ABBA | Taiwan, Kina |

| 2 | Pālua wili pōpō | HIWIN/PMI | Taiwan, Kina |

| 3 | CNC | Siemens | Kelemānia |

| 4 | mīkini servo | Siemens | Kelemānia |

| 5 | Mea hoʻokele servo | Siemens | Kelemānia |

| 6 | ʻO ke wili pololei | KENURN | Taiwan, Kina |

| 7 | Lubrication kikowaena | ʻO BIJUR/HERG | ʻAmelika Hui Pū ʻIa / Iapana |

Nānā: ʻO ka mea i luna aʻe ko mākou mea hoʻolako maʻamau. Hiki ke pani ʻia e nā ʻāpana like o nā lama ʻē aʻe inā ʻaʻole hiki i ka mea hoʻolako i luna ke hoʻolako i nā ʻāpana inā he mea kūikawā.

ʻIke Pōkole o ka ʻOihana  ʻIke Hale Hana

ʻIke Hale Hana  Ka Mana Hana Makahiki

Ka Mana Hana Makahiki  Ka Mana Kālepa

Ka Mana Kālepa